Count on absolutely reliable and highly qualified specialists for your chemical project.

Schmidbauer guarantees safe solutions. Seamless safety and strict compliance with international quality standards are the substantial basis of our actions. Assurance that is indispensable when working in sensitive environments such as refineries. Combined with our special equipment and exemplary flexibility, we adapt exactly to your required capacities to ensure maximum time and cost efficiency.

Our service portfolio:

- Plant scheduled maintenance (standstills)

- Maintenance during operation

- Construction of new plants

- Expansion of existing plants

- Transport & logistics of new modules ex works

- Basic assembly

Our Certification:

- Occupational safety SCC** (Safety Certificate Contractor)

- Quality Management ISO 9001:2015

- Energy management ISO 50001:2011

our projects from chemical industry spectacular references

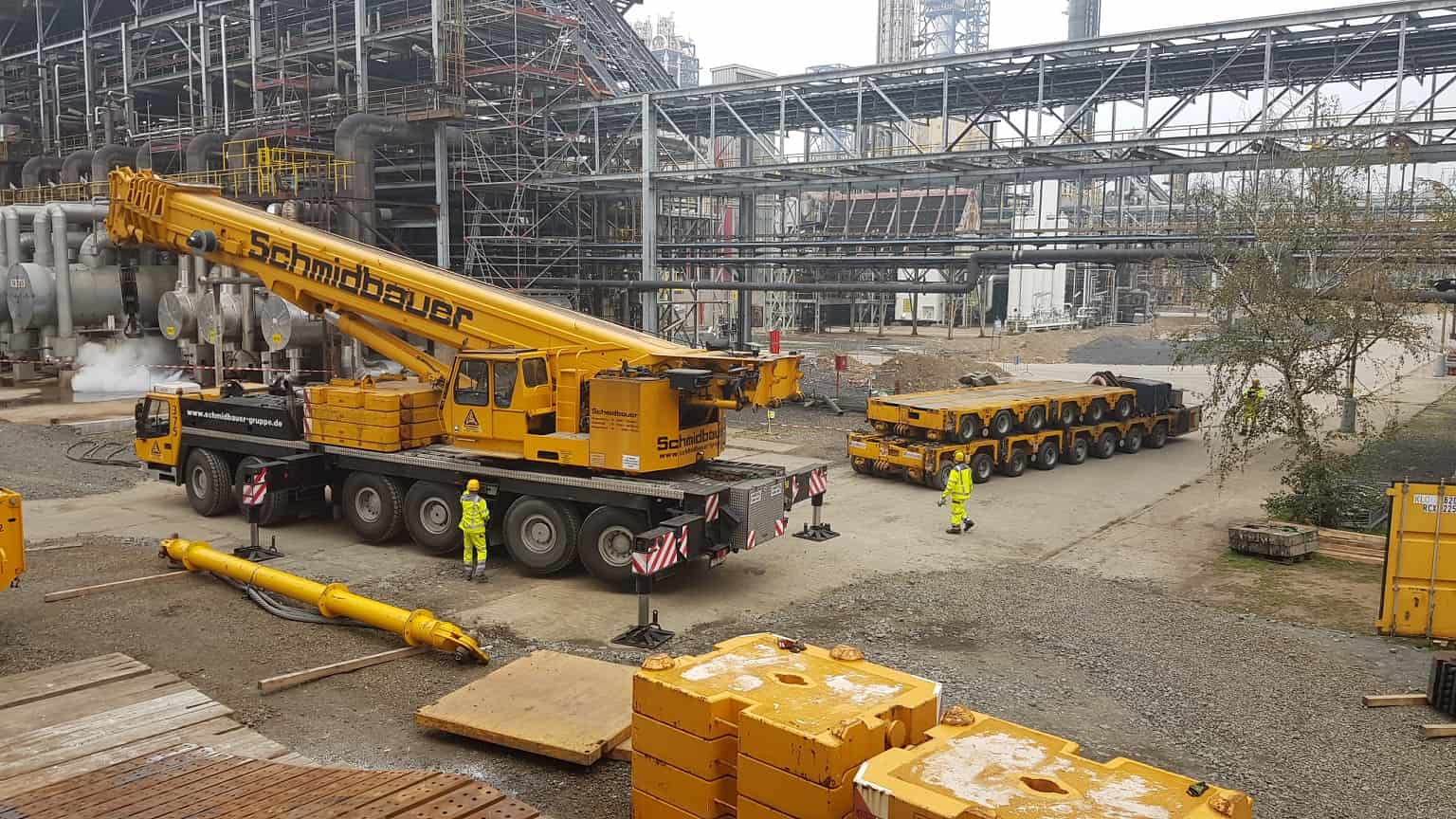

Transporting and lifting of a heat exchanger and steam drum

Cross transport of a 160 t heat exchanger and a 35 t steam drum within the Unipetrol plant in Litvinov, Czech Republic.

Then alignment by means of an auxiliary crane and lifting over a pipe rack with subsequent lifting over the building roof.

The 14-axle self-propelled Powerboosters picked up the 160 t heat exchanger and moved it within the plant to the main crane.

Now the trailing crane was positioned behind the transporter. The main and tracking crane and the main beam was attached. Our special deflection rollers were used. After erecting the heat exchanger, it had to be lifted over an existing pipeline. Then the crane could swivel by 90 degrees and move by approx. 10 m. Only shortly before being inserted into the roof opening could the component be turned into the correct position by means of guide ropes to avoid a collision with the mast of the crane. Now it was still necessary to insert the component into the building with centimeter precision.

The same procedure was followed with the steam drum. Here, the main crane had to be moved 3 m further back due to the interfering ege.

Thanks to our detailed planning, the lifting activites could be carried out very precisely.

Special features:

Construction length for the crane limited, so that the lifting height of the crane was minimal à a high interferering edge required a special method statement for lifting, which had to be followed exactly. Spreader Beam with roller set for lifting

Equipment:

- LR 1600/2 HSLDB 78 m

- GMK 6300

- Intercombi power booster with 14 axles

- Modulift spreader beam with deflection rollers

Location: Litvinov, Czech Republic

Period: October 2019